Description

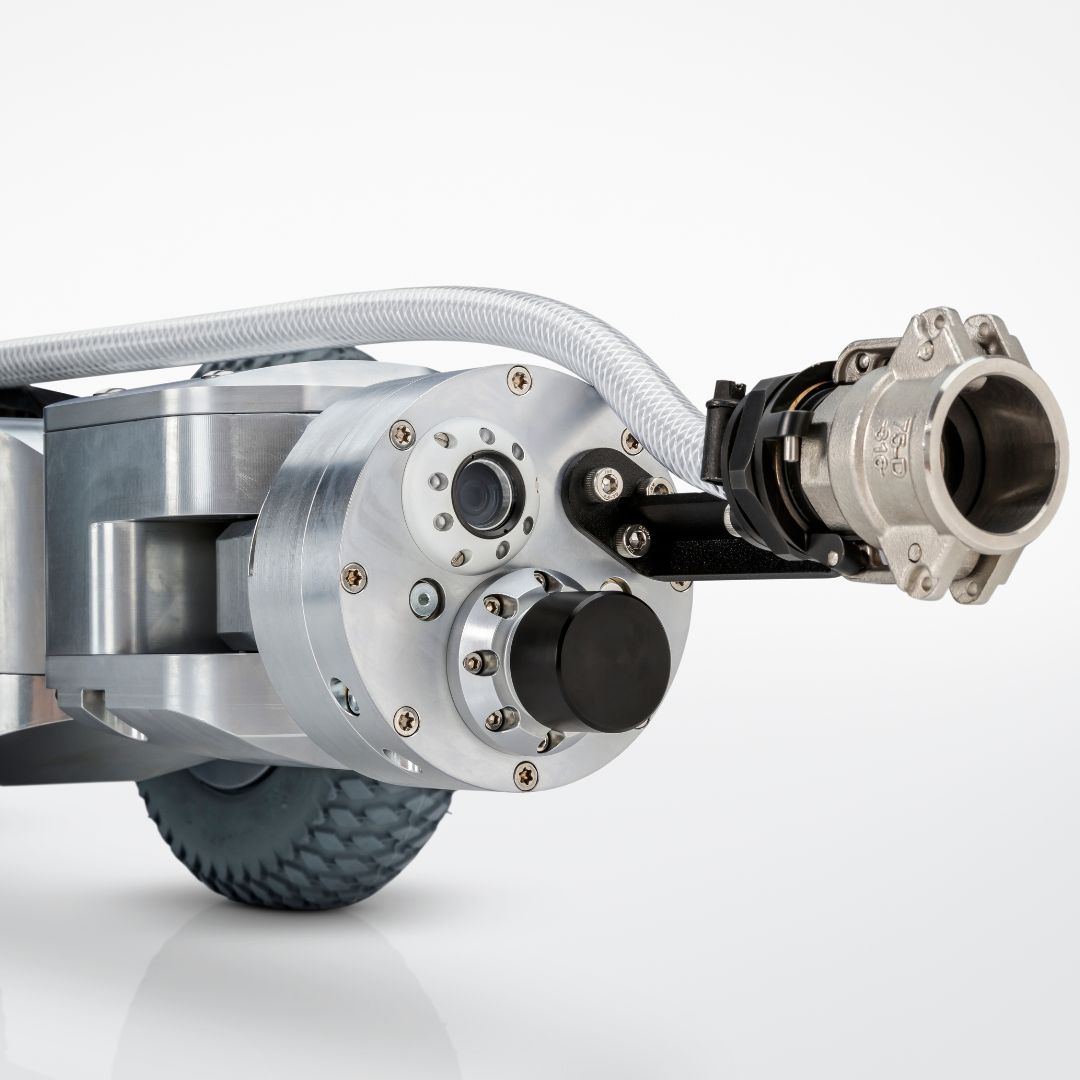

The IBAK MicroGator® Air is a high-performance pneumatic cutting robot designed for advanced sewer rehabilitation and reinstatement work.

Combining powerful cutting capability with IBAK’s proven modular MainLite platform, the MicroGator Air offers exceptional flexibility, reliability, and operational efficiency for contractors working in medium to large diameter pipelines. Engineered in Germany to the highest quality standards, the MicroGator Air delivers precise, controlled cutting performance while remaining compact, mobile, and easy to deploy – making it an ideal solution for modern drainage and rehabilitation professionals.

The MicroGator® Air is a pneumatically driven robotic cutter developed for main sewer applications ranging from DN200 (relined) up to DN800. Designed to operate as either a vehicle-mounted system or a fully mobile rehabilitation unit, it offers unmatched versatility across a wide range of site conditions and operational requirements.

Fully compatible with the IBAK MainLite inspection platform, the MicroGator Air allows contractors to combine cutting, rehabilitation, and CCTV inspection into a single integrated system. Using modular components such as KW206/306 cable winches and BP100 control units, operators can quickly configure a complete cutting and inspection setup using shared infrastructure – maximising efficiency and reducing equipment investment.

Powered by a high-performance pneumatic motor, the MicroGator Air delivers powerful and consistent cutting performance while maintaining low noise output, making it suitable for both urban and residential environments.

Features & Benefits

High-Performance Pneumatic Cutting

- Powerful air-driven motor delivers precise, high-torque cutting for concrete, roots, liners, and intruding connections.

- Continuous pressure monitoring ensures safe, stable and controlled operation.

Modular, Scalable System Design

- Fully compatible with IBAK MainLite tractors, control units and winches, allowing flexible system configuration.

- Easily expandable for inspection, cutting, top-hat installation, and ultra-high-pressure jetting, maximising ROI.

Advanced Visual Monitoring

- Integrated CutterCam with air-shield cleaning system provides a consistently clear view of the cutting zone.

- Rear-facing camera supports safe reversing and precise positioning.

Operational Efficiency & Safety

- Fourth-axis articulation enables high-precision cutting at complex angles.

- Can be deployed as mobile or vehicle-mounted, providing flexibility across varied job sites.