Description

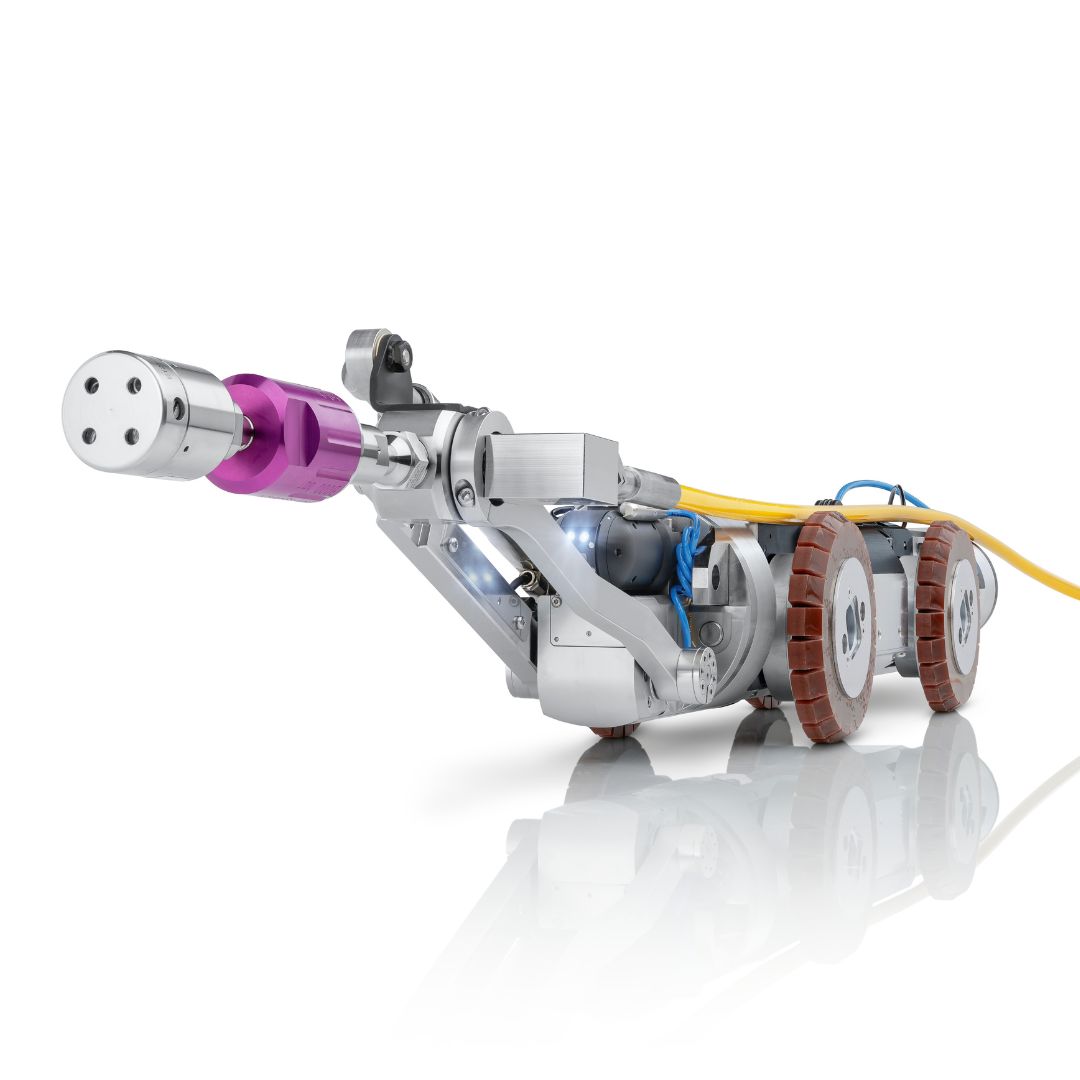

The IBAK MicroGator® GT – UHP (Ultra High Pressure) is a state-of-the-art robotic rehabilitation system engineered to deliver maximum cutting and cleaning performance using ultra high-pressure water technology.

Designed for demanding sewer environments, it combines extreme power with precise robotic control, enabling contractors to complete complex rehabilitation tasks safely, efficiently, and to the highest professional standards. Developed and manufactured in Germany, the MicroGator GT-UHP reflects IBAK’s commitment to engineering excellence, reliability, and innovation – offering drainage professionals a powerful solution for high-performance cutting, milling, and surface preparation.

The MicroGator® GT – UHP is designed for DN200 to DN800 pipelines and operates using ultra high-pressure water jets of up to 2,500 bar, delivering outstanding material removal performance without mechanical cutting tools. This makes it ideal for liner reinstatement, concrete removal, root cutting, deposits removal, and precision milling, even in extremely hard materials.

Built on IBAK’s modular robotic platform, the GT-UHP integrates seamlessly with existing MainLite tractor systems, control units, and winches, enabling flexible system configuration for both vehicle-mounted and mobile rehabilitation setups. This modularity allows operators to rapidly deploy a complete UHP cutting solution while minimising equipment investment.

Advanced robotic articulation, combined with intelligent pressure regulation and high-definition camera systems, ensures precise control and safe operation — even in confined or structurally compromised pipe networks. The result is a powerful, highly controllable rehabilitation tool capable of delivering exceptional results across a wide range of sewer environments.

Features & Benefits

Ultra High-Pressure Water Jet Technology

- Water pressures up to 2,500 bar deliver exceptional cutting, milling, and surface cleaning performance.

- Non-mechanical cutting reduces tool wear and maintenance requirements while improving operational safety.

- Highly effective for liner reinstatement, concrete removal, roots, scale, and heavy deposits.

Precision Robotic Control

- Advanced articulation allows accurate targeting and controlled material removal, even in complex pipe geometries.

- Proportional pressure regulation ensures consistent cutting performance and reduced risk of pipe damage.

- High-resolution CutterCam provides clear, real-time visual feedback for precise operator control.

Modular & Scalable System Design

- Fully compatible with IBAK MainLite tractors, winches, and control systems.

- Can be deployed as a vehicle-mounted or mobile rehabilitation unit.

- Supports rapid configuration changes to match varying job requirements, maximising uptime and productivity.

Safety, Reliability & Efficiency

- Continuous pressure monitoring enhances operator safety and system protection.

- Robust industrial construction ensures long service life in harsh sewer environments.

- High productivity reduces job times, minimising operational disruption and overall project costs.