Description

CL70 Electric Milling Robot – Advanced Technology for Efficient House Connection Cutting

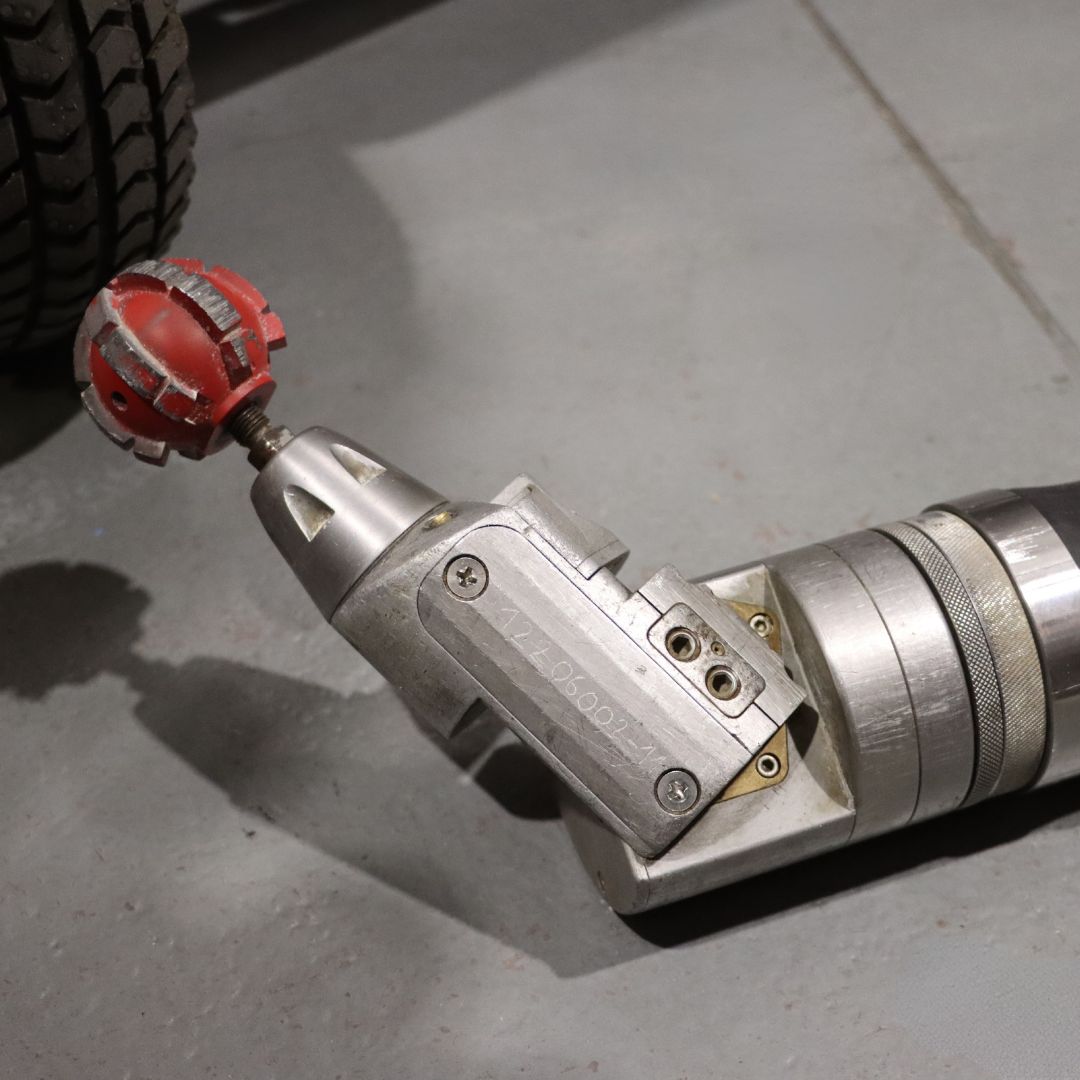

Launched two years ago, the CL70 electric milling robot (from DN75) has quickly become a trusted solution for efficient and reliable house connection cutting. Combining innovative engineering with a refined design, the CL70 delivers outstanding performance, durability, and operational efficiency for demanding site environments.

The CL70 is engineered to easily navigate 90° pipe bends and manage diameter transitions up to DN250 without the need for time-consuming adjustments. This is achieved through its highly flexible tensioning bladders and pneumatic feed system. For larger pipe applications, the system can also be deployed in pipe diameters up to DN300 when used with the optional push carriage.

A key advantage of the CL70 is its modular system architecture, allowing operators to configure the equipment based on individual project requirements. The most compact setup consists of the milling robot and a battery-powered control unit, providing a cost-effective entry solution. For users requiring enhanced capability, additional modules are available, including a compact compressor case, dedicated tool storage, and an ergonomically designed transport trolley.

At the core of the CL70 is a high-performance 800W water-cooled electric motor, delivering powerful, consistent cutting performance. The milling head benefits from a durable internal protective coating, ensuring excellent resistance to water ingress and long-term operational reliability. A high-definition camera system provides crisp, real-time visuals, with built-in recording functionality for straightforward documentation directly via the control unit — no external software required.

Key Features & Benefits

- State-of-the-art technology delivering exceptional productivity and operational reliability

- Modular design with configurable case units to suit a wide range of applications

- Highly mobile system, featuring an ergonomic transport trolley with integrated docking for the control unit

- Smooth passage through 2 × 45° or 1 × 90° bends during both insertion and retrieval

- Centralised pipe clamping for stable and precise operation

- HD colour camera with adjustable LED illumination

- Integrated 5-litre water tank with combined air and water camera cleaning

- Operation via an equipment trolley with joystick and touchscreen interface (PLC controlled)

- High-contrast display for clear visibility in all conditions

- Intelligent sensor system with real-time status notifications

- Water-cooled milling motor for extended duty cycles

- Supplied with four rechargeable batteries and rapid charger, achieving full charge in approximately 45 minutes

- System pressure-rated to 1 bar

- Integrated recording system with internal hard drive and USB export

- Ready for operation with minimal setup or configuration required